Combustion chambers and reactors

For research purposes, I-TPT supplies tailor-made combustion chambers and reactors including the associated control technology. One focus here is on combustion test benches that can be operated at temperatures of up to 2200 °C and high pressure. The systems allow, for example, the laser-optical investigation of combustion processes, material tests under extreme conditions or the provision of hot gas with defined properties.Burner test rig

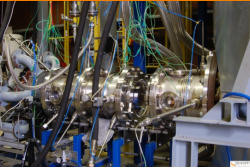

The joint burner test bench of the Institute for Turbomachinery and Fluid Dynamics and the Institute for Technical Combustion of the Leibniz University Hannover has been equipped with a new test combustion chamber in order to be able to carry out combustion tests and also to enable the application of new measurement techniques. The burner test bench is used to carry out extensive tests on flames and exhaust gas jets. In order to allow a high variability of the burner test bench, the combustion chamber has a modular design. It is composed of individual main segments, which can be exchanged with each other, so that the measuring technique can be applied at different places. The burner test bench is used within the framework of the Collaborative Research Centre 871: Regeneration of Complex Capital Goods.High pressure porous burner

In a collaboration between the Chair of Fluid Mechanics at the University of Erlangen Nuremberg and Evonik Industries AG, a high-pressure burner was developed that is used for gas-dynamically initiated particle production (GIP). The highlight of the high-pressure burner is the stabilization of the combustion reactions in a ceramic foam. This enables stable combustion over a wide power modulation range at pressures between 1 bar and 10 bar. The test bench also allows an exact adjustment of the gas temperature and the oxygen concentration, which is decisive for the downstream GIP reactor.Combustion chamber for laser-optical investigation of the

mixing behaviour of hot gasesT

The combustion chamber is heated by a modulating burner (diesel) and can be operated at pressures of up to 10 bar and gas temperatures of up to 500 °C. The combustion chamber is surrounded by cooling air. The combustion chamber is surrounded by cooling air, which is mixed with hot exhaust gas downstream of the combustion chamber. This prevents the resulting hot exhaust gas from coming into direct contact with the combustion chamber wall. 12 integrated sight glasses with a clear width of 150 mm each allow good optical access. The individual modules can be exchanged at will so that measurements can be taken at almost any point along the combustion chamber axis.

PRODUCTS

porous burner

metal fibre burner

industrial furnaces

combustion technology

combustion chambers

and reactors

ceramic pieces

consulting and training

Issendorff Thermoprozesstechnik e.K. I Adalbert-Stifter Str. 13 I D-91054 Erlangen I info@-tpt.de I USt-IdNr.: DE 268 299 066

o

Brennkammern für hohe Drücke und

Temperaturen

o

Luft- oder wassergekühlt

o

Optische Zugänglichkeit

o

Druckgeräterichtlinie 97/23/EG

o

Modularer Aufbau

Eigenschaften