High temperature insulations and ceramic components

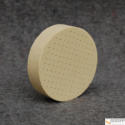

I-TPT supplies thermal insulation materials and ceramic components for thermal process plants and other high-temperature apparatus. Examples: • insulation boards • ceramic fibre products • lightweight refractory bricks • vacuum formed parts • insulation systems • quartz glass for high-pressure applications • SiC foam ceramics I-TPT manufactures ceramic components for high temperature applications as single pieces or in small quantities. These are used e.g. in test benches or combustion chambers and can withstand temperatures up to 2200 °C. Perforated plates can be used for hot gas distribution, as flame arresters for porous burners or for introducing cooling air into combustion chambers. Evenly arranged bores with small diameters are used for gas distribution. Vacuum mould plates are processed for this purpose, which can be used up to temperatures of approx. 1600 °C. These plates are machined by drilling and milling. The minimum bore diameter is approx. 0.6 mm. An interesting new development are perforated plates that are no longer drilled. The materials used are casting compounds based on zirconium dioxide (ZrO2) or aluminium oxide (Al2O3). The casting process avoids damage to the green body caused by drilling individual holes. In addition, the diameter of the holes can be reduced to 0.1 mm.

PRODUCTS

porous burner

metal fibre burner

industrial furnaces

combustion technology

combustion chambers

and reactors

ceramic pieces

consulting and training

Issendorff Thermoprozesstechnik e.K. I Adalbert-Stifter Str. 13 I D-91054 Erlangen I info@-tpt.de I USt-IdNr.: DE 268 299 066

Hochtemperaturprodukte

o

Einsatztemperaturen bis 2000°C

o

Lieferung kleiner Mengen möglich

o

Individuelle Lösungen

o

Beratung vor Ort

o

Einsatz von Berechnungs- und

Simulationsprogramme